Experimental facilities / Experimental facilities for the railway industry

WTtech.CZ manufactures experimental facilities and test equipment for many industries including the railway industry. We have recently completed significant projects for the rolling stock industry – bearing test equipment and test equipment to measure railway vehicles’ braking systems.

We supply experimental facilities developed and designed by us including their modifications, and experimental facilities designed and constructed according to the exact customer’s conditions and requirements. Our services are not limited to the equipment, we offer a comprehensive service including the supply of all equipment, programming of measuring and control software, project management, research project

preparation, and expert consultation.

Construction at WTtech.CZ is conducted exclusively in a 3D CAD system using Creo software, which enables detailed design and modeling of all testing facility components. The design data is stored and managed in the Windchill PDM system, ensuring efficient product lifecycle management and easy access to all necessary information.

Design optimization includes FEM (Finite Element Method) and CFD (Computational Fluid Dynamics) analyses. These analyses allow the simulation of the components’ mechanical and fluid behavior before they

are manufactured, resulting in high product quality and reliability.

WTtech.CZ control and measuring systems are based on the PLC (Programmable Logic Controller) technology and measurement of selected parameters by industrial computers. This guarantees the resulting products’ exceptional accuracy and reliability.

Testing facility control and measurement is usually implemented in the LabVIEW user interface. This enables efficient test automation, minimizes the need for human intervention, and increases efficiency and measurement accuracy while offering intuitive visualization and analysis of measured data.

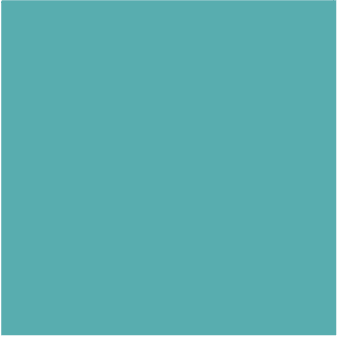

The bearing test rig (BTR) is one of the unique devices developed by WTtech.CZ. It is designed for testing the endurance of axle bearings and bearing houses. Bearing fatigue tests consist of loading the bearing with axial and radial forces at specific speeds. A BTR can simulate speeds up to 300 km/h, including the simulation of airflow around the bearing units according to the relevant standard.

The tests run almost uninterrupted for several months, which is why the BTR proposal focuses mainly on the high rigidity and durability of all components used and the reliability of the entire BTR in long-term operation. The BTR serves many customers, which enables us to continuously optimise the technology used and refine the measurement process.

according to the ČSN EN 12 082

24/ 7/ 365 for up to 9 months

up to 300 km/h

20 °C ± 2 °C

up to 500 kN/axle

± 30 kN

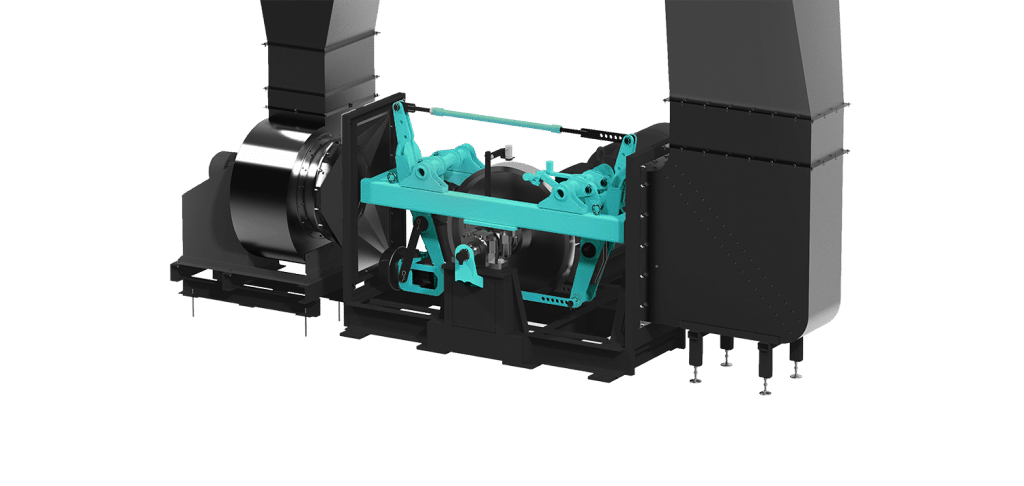

The Brake Test Rig (BrTR) is a device designed for railway vehicle wheel thermomechanical testing. It allows detailed simulation of the braking processes including long-term braking during driving and an accurate measurement of the resulting deformations and temperatures. Braking is simulated by attaching a loading device representing the mass of the trainset per wheel. The BrTR is equipped with an advanced ventilation system simulating the airflow around the wheel, and high-precision measuring instruments for continuous data acquisition and evaluation.

The BrTR uses an automated control and measurement system to ensure accurate

and reliable analysis of the braking performance and mechanical behaviour of the wheels during testing. This system minimises the need for human intervention,

increasing the tests’ efficiency and accuracy.

up to 60 km/h

up to 50 kW at constant speed

4 s ± 0,2 s

8,4 m/s according to the relevant standard

Continuous, non-contact

Measures deformations up to 10 mm

Measurement accuracy of 0,1 mm

up to 800 °C

Single or double-sided braking

Project study, feasibility study, budget estimate

Identification of the requirements and standards that the experimental facility must meet; Technology design proposal for all parts (mechanical, propulsion, measurement, control)

Definition of the building requirements for the laboratory (foundations, spatial layout, air conditioning, soundproofing, control room); Definition of resource requirements (electricity, water, air, hydraulics); Preparation of a detailed building design or detailed specifications

Design in the Creo 3D CAD system, FEM, and CFD analysis; Selection of sub-components (mechanical parts, sensors, pneumatic and electrical parts, etc.); Simultaneous preparation of electrical documentation and pneumatic/hydraulic schematics; Risk analysis

After customer approval, purchase of material, components/parts, and production, basic assembly and partial recovery of subsystems at the WTtech.CZ premises begins

Production of switchboards, measuring, and control systems Programming of measuring and control software (PLC, DAQ systems)

Transportation, installation, and launch of the test equipment at the customer‘s site; Electrical inspections; Calibration of the measuring chain in an accredited laboratory

Trial operation and training of customer operators; Launch of live operation

Preparation of operating documentation, operating and maintenance manuals; CE certificate issuance

After-sales support and consultation on all operation-related matters; Remote device management and user support via a dedicated VPN connection

We are a company with many years of experience in the field of experimental aerodynamics, operating in a wide range of activities, including the development and research of test and measurement equipment such as wind tunnels and their accessories, the development of data processing software, consulting activities in the field of aerodynamics and the preparation of research projects.

WTtech.CZ s.r.o.

Lhotecká 214, 290 01 Sokoleč

Czech Republic

IČ/DIČ: 28537335/CZ28537335

GDPR

The company is registered in the Commercial Register maintained by Municipal Court in Prague, Section C, Insert 148790