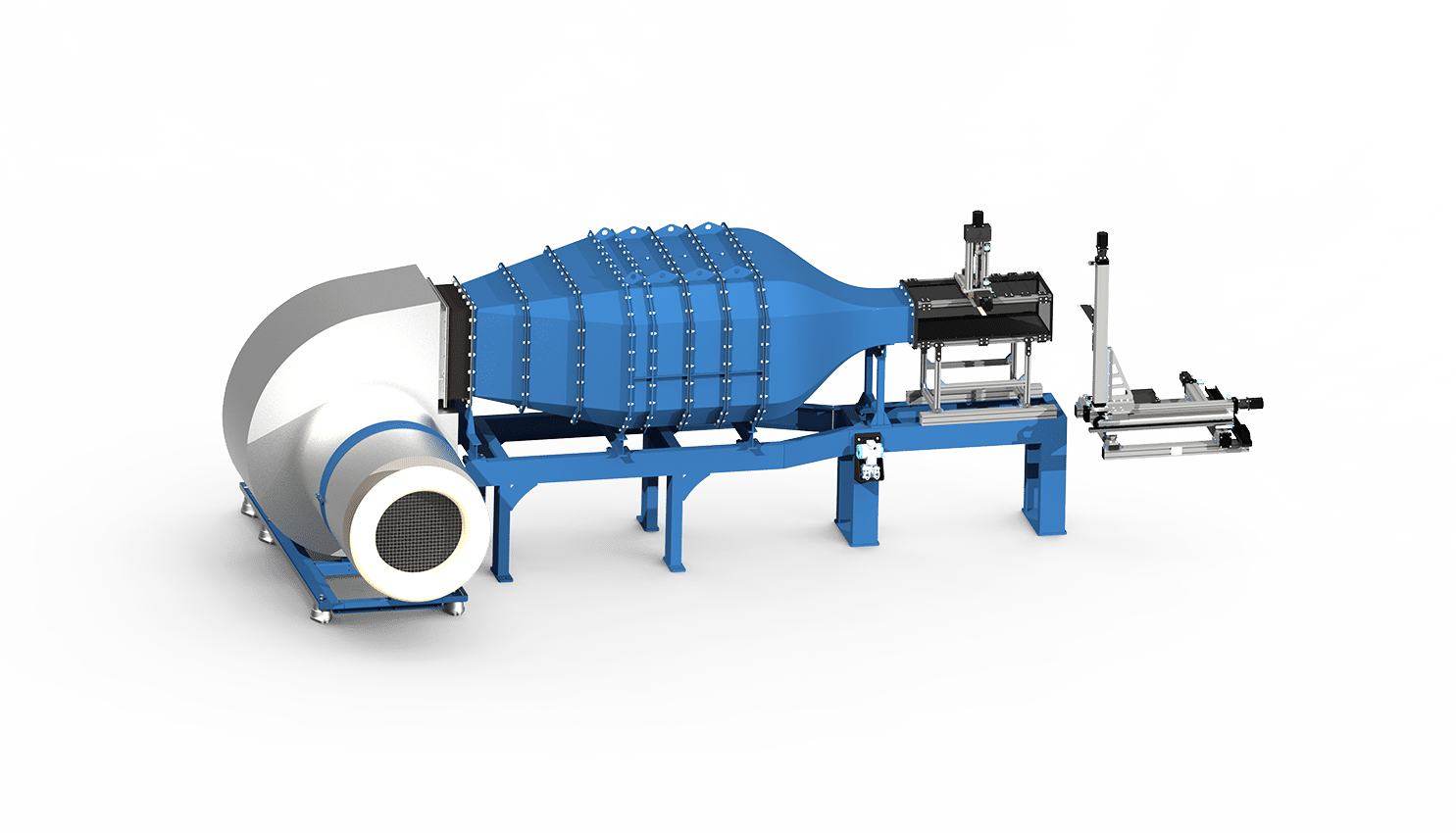

Wind tunnels / Accessories

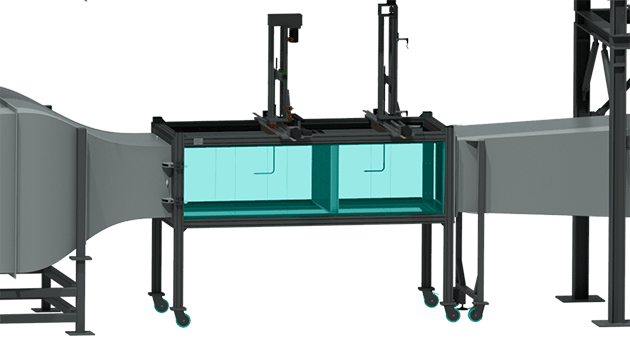

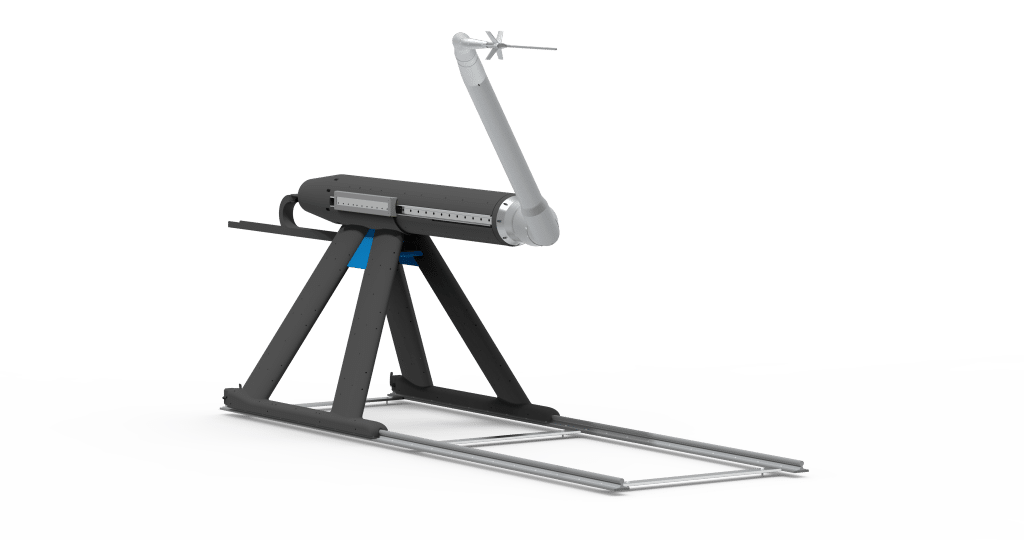

Traverse Mechanisms and manipulators are key accessories for wind tunnels and experimental facilities used for various types of research, including fluid mechanics. They are used for precise positioning and control of models or probes, enabling flow field characteristic measurement in the wind tunnel‘s Test Section. Traverse Mechanisms move probes and sensors in different axes, which is essential to obtain detailed data on airflow and other aerodynamic properties in the area of interest.

They are designed and constructed for maximum position accuracy, minimum

interference with the flowfield, and the ability to withstand extreme conditions such as high flow velocities and high temperatures.

the simplest traverser type, where the movement is controlled manually,

suitable for basic applications where high precision or automation is not required

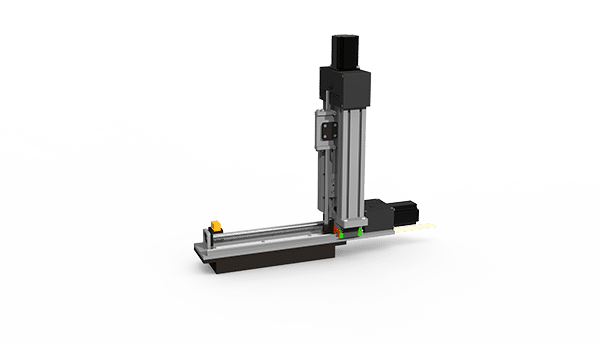

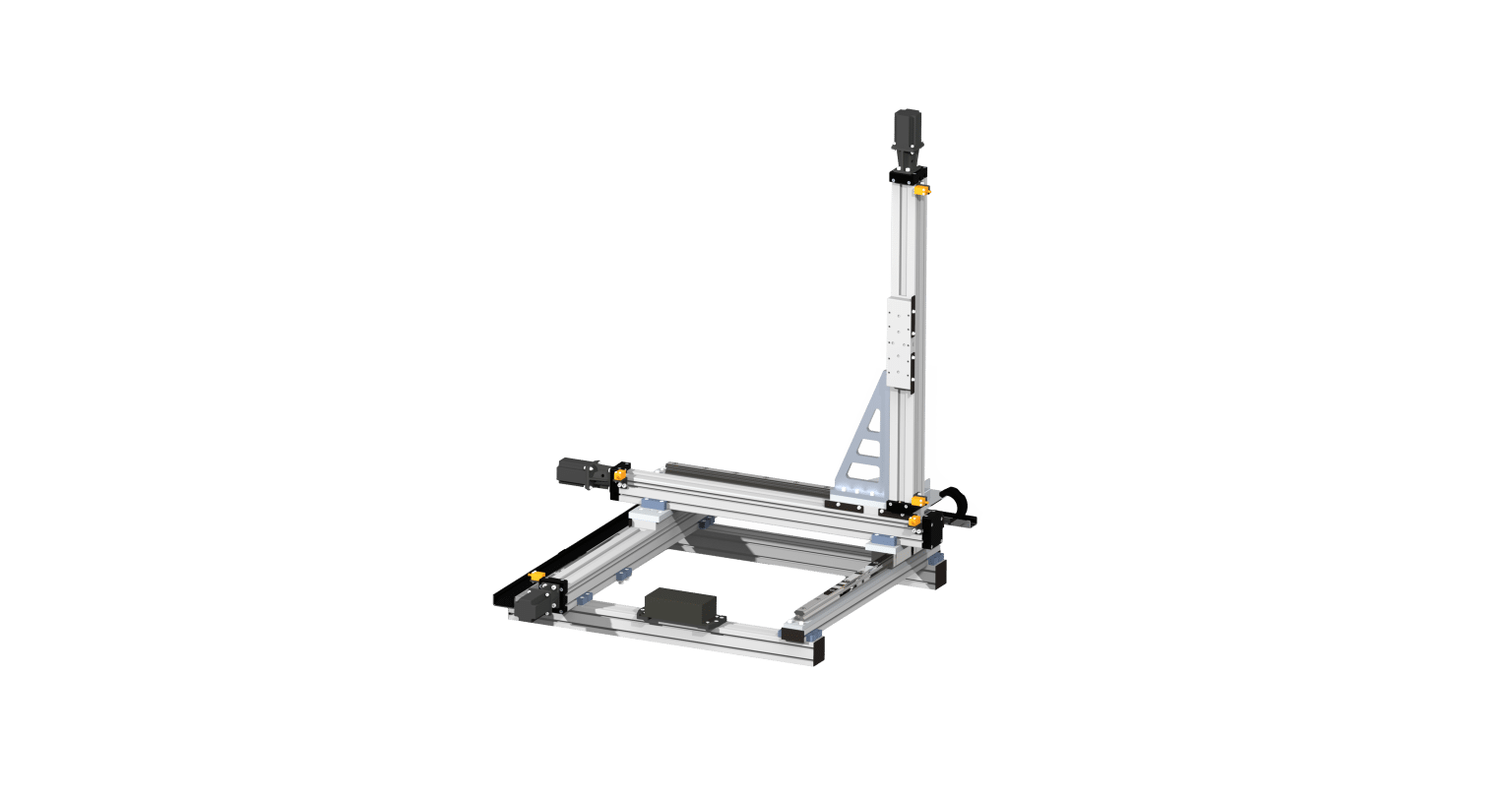

these traversers offer high precision and reliability and are capable of performing fine steps; they are ideal for applications that require precise positioning

provide higher performance and precision than stepper motor traversers and can be used to quickly and smoothly change position, are suitable for highly demanding applications requiring dynamics and precision

move on one axis, used for basic measurements requiring only linear displacement

move on two axes, allowing for more complex automatic measurement in a two-dimensional space

move on three axes and are essential for complex three-dimensional measurements and analyses

combine the above with additional probe adjustment options

WTtech.CZ offers a wide range of traversing devices designed to suit the customer‘s requirements and conditions, including the size of the area to be surveyed. The control software allows for scheduling of the measurement in predefined steps and intervals, while the traversing process is fully automated and can take from a few minutes to several hours depending on the type of measurement.

The traversers can be controlled both manually with buttons on control panel and solely via a software interface. The traverse mechanisms can move in predefined steps or continuously. In order to increase the safety of the measurement, the movement of the traversers is restricted by software and hardware limits.

The design of WTtech.CZ traversers minimizes the traverser’s influence on the test airflow and is optimized using the finite element method (FEM). This ensures high structural stiffness, minimizes deformation during operation, and contributes to high measurement accuracy. FEM optimization also ensures that the traversers have optimal natural frequencies, reducing their susceptibility to vibrations caused by external forces. This increases the stability and reliability of measurements in challenging aerodynamic conditions.

WTtech.CZ s.r.o.

Lhotecká 214, 290 01 Sokoleč

Czech Republic

IČ/DIČ: 28537335/CZ28537335

GDPR

The company is registered in the Commercial Register maintained by Municipal Court in Prague, Section C, Insert 148790