Experimental facilities / Experimental facilities for industrial research and development

WTtech.CZ offers unique test rigs and equipment, including research and development equipment in mechanical engineering, hydraulic engineering, and aerodynamic testing—the WTtech.CZ team consists of committed designers, engineers, constructors, and mechanical specialists. Thanks to our expert know-how and many years of experience, we can offer solutions for any specialized project completed under difficult circumstances.

WTtech.CZ manufactures experimental facilities and test equipment for many industries. Our test equipment and components, as well as their implementation at customer sites, meet the highest quality, safety, and maximum test reliability requirements. In addition to hardware solutions, WTtech.CZ offers comprehensive support from initial design to implementation and operation.

In addition to the design and construction of experimental facilities, WTtech.CZ is also well-versed in design using the Creo 3D CAD system, advanced aerodynamic calculations as well as CFD and FEM simulations. We also offer specific measurement and control software, data processing and analysis for design optimization, and effective solutions to challenges in aerodynamics.

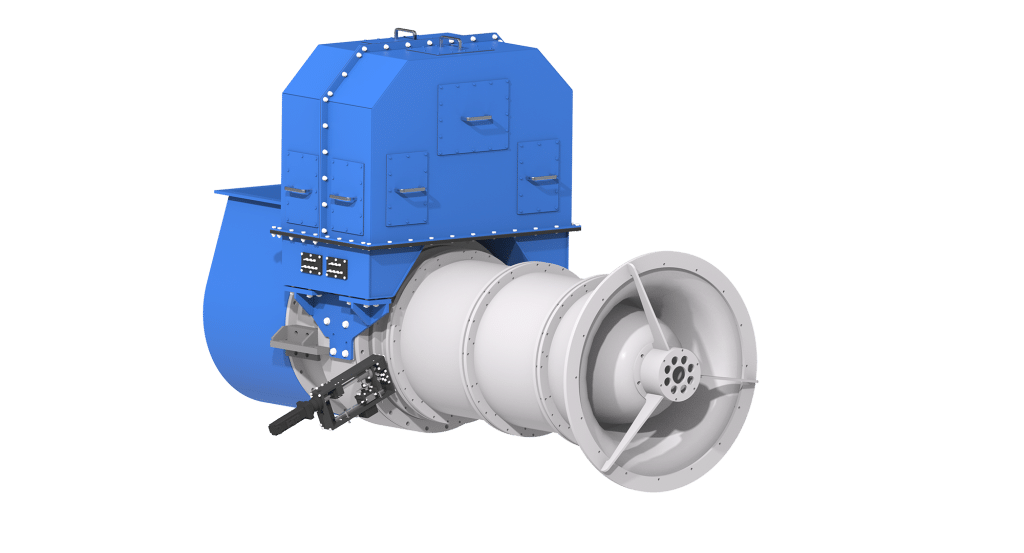

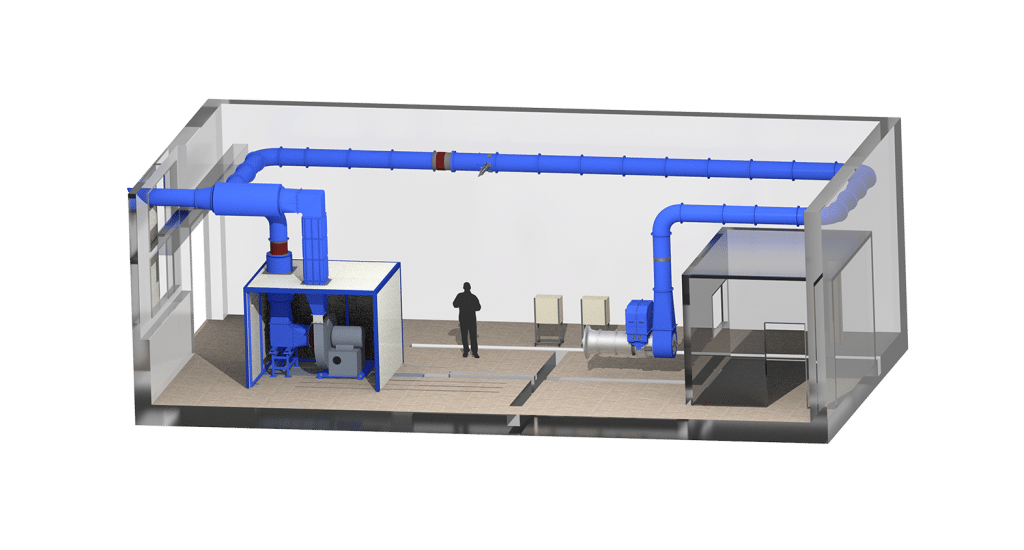

The experimental facility for measuring turbines’ aerodynamic characteristics is equipped with technology that allows accurate and efficient testing of turbine stage performance. The experimental facility includes a single-stage turbine model located in the facility intake and connected to a dynamometer to measure overall performance parameters. Its recent upgrade focused on rebuilding the turbine measurement apparatus

The project was implemented on a turnkey basis, including the dismantling and disposal of parts of the old equipment, integrating new components into the existing system, supply of complete technical documentation, and operator training for a seamless transition to the upgraded infrastructure.

The project to build a laboratory for testing fuel nozzles of aircraft engines was implemented on a turnkey basis. The main measuring equipment is a PDA (Phase Doppler Anemometry) system, a non-intrusive optical method for temporally and spatially resolved measurements in a two-phase environment. This system offers the ability to simultaneously measure the size, rate, and time of individual particle detection (droplets, bubbles, entrained particles) based on reflection and refraction of light in a small measurement volume.

2D Phase Doppler Analyzer performs point measurements and traversals in 2D or 3D grids, allowing the entire area of interest to be measured. The results can be used for a quantitative description of the flow and serve as input data for numerical simulations.

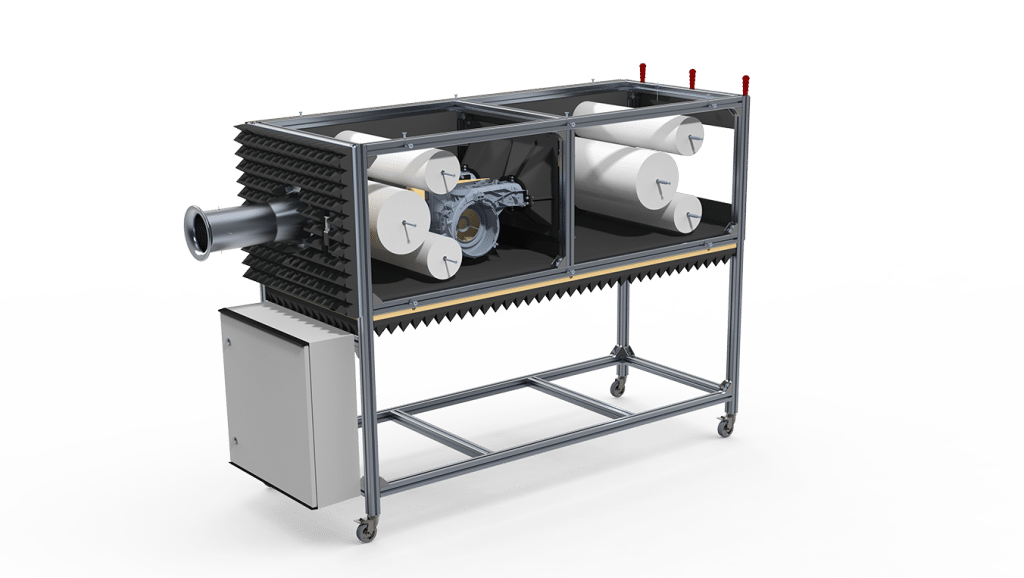

The examination facility was designed specifically for measuring and testing air conditioning systems in the automotive industry. The design includes a soundproof enclosure open on one side with an air intake nozzle on the other, allowing efficient regulation and measurement of airflow.

Radial fans are installed in the box to ensure the necessary airflow. Flow rate can be controlled roughly by a lever-operated flap and subtly by a stepper motor. The flow is measured by pressure sensors located on the nozzle and in front of the outlet. The data is evaluated by a measuring card and software developed in the LabVIEW environment.

The measurement results, including mass flow rate and air resistance, are displayed on the computer and stored in text files. SoundBOX provides accurate and reliable testing in a controlled environment, making it a highly effective development tool for automotive air conditioning systems.

Project study, feasibility study, budget estimate

Identification of the requirements and standards that the experimental facility must meet; Technology design proposal for all parts (mechanical, propulsion, measurement, control)

Definition of the building requirements for the laboratory (foundations, spatial layout, air conditioning, soundproofing, control room); Definition of resource requirements (electricity, water, air, hydraulics); Preparation of a detailed building design or detailed specifications

Design in the Creo 3D CAD system, FEM, and CFD analysis; Selection of sub-components (mechanical parts, sensors, pneumatic and electrical parts, etc.); Simultaneous preparation of electrical documentation and pneumatic/hydraulic schematics; Risk analysis

After customer approval, purchase of material, components/parts, and production, basic assembly and partial recovery of subsystems at the WTtech.CZ premises begins

Production of switchboards, measuring, and control systems Programming of measuring and control software (PLC, DAQ systems)

Transportation, installation, and launch of the test equipment at the customer‘s site; Electrical inspections; Calibration of the measuring chain in an accredited laboratory

Trial operation and training of customer operators; Launch of live operation

Preparation of operating documentation, operating and maintenance manuals; CE certificate issuance

After-sales support and consultation on all operation-related matters; Remote device management and user support via a dedicated VPN connection

We are a company with many years of experience in the field of experimental aerodynamics, operating in a wide range of activities, including the development and research of test and measurement equipment such as wind tunnels and their accessories, the development of data processing software, consulting activities in the field of aerodynamics and the preparation of research projects.

WTtech.CZ s.r.o.

Lhotecká 214, 290 01 Sokoleč

Czech Republic

IČ/DIČ: 28537335/CZ28537335

GDPR

The company is registered in the Commercial Register maintained by Municipal Court in Prague, Section C, Insert 148790